CUTTING EDGE BUT TAKING THE STING OUT OF YOUR COSTS

PRECISION. QUALITY. HIGH PERFORMANCE

Scorpion Tooling are a UK cutting tool manufacturer specialising in tool design and optimisation for the machining of advanced materials.

Since 1990 we have provided the very best tools to meet the individual needs of our clients.

Certified ISO 9001 and actively investing in R&D for advanced manufacturing.

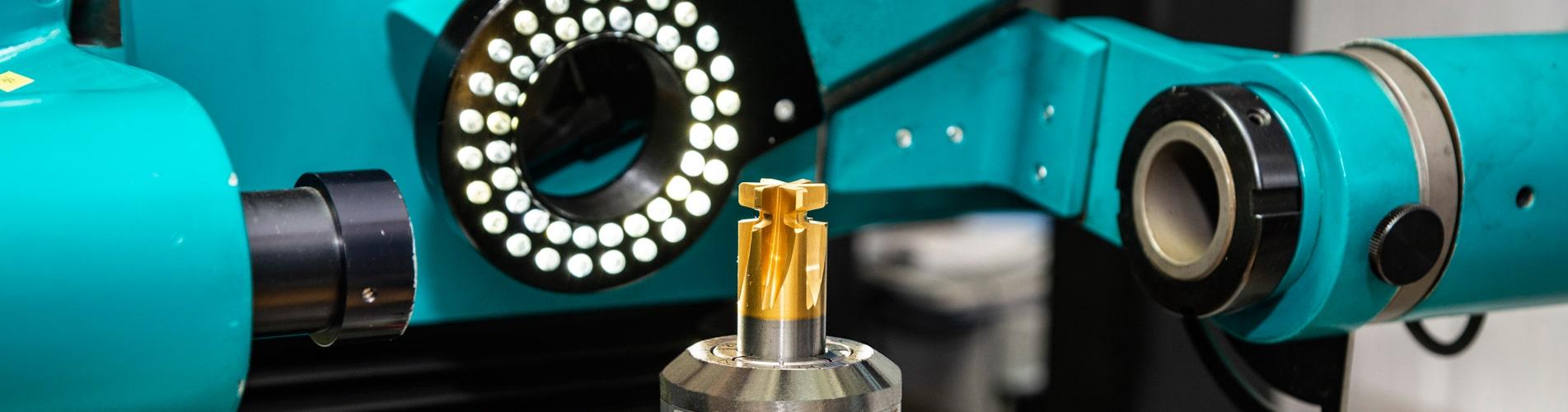

Our ability to test performance in-house on our computer controlled optical measuring equipment gives our customers peace of mind knowing

our tools have been tested to meet all requirements before they leave our facility.

We deliver on quality and performance.

Why Choose Scorpion?

Our Team

We have a dedicated team committed

to providing friendly and helpful services

as well as quality products.

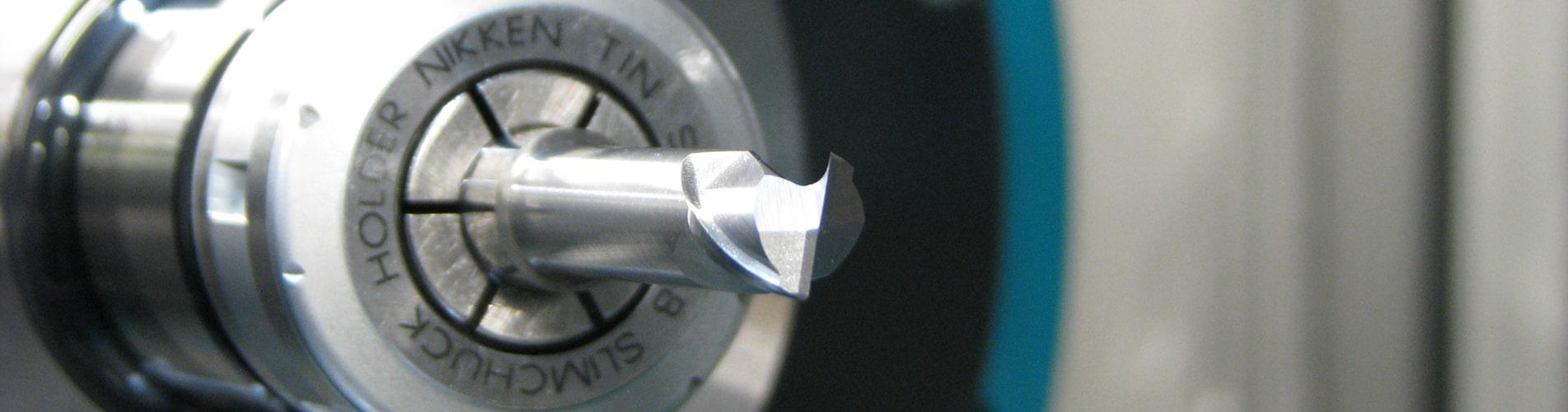

Bespoke Tooling

With our expertise, we can manufacture

a specific tool to suit your unique applications

within a few days if necessary.

Technical support

We work closely with our customers

to ensure a full machining solution can be

provided for every production job.